Date: 25 Jun 2021

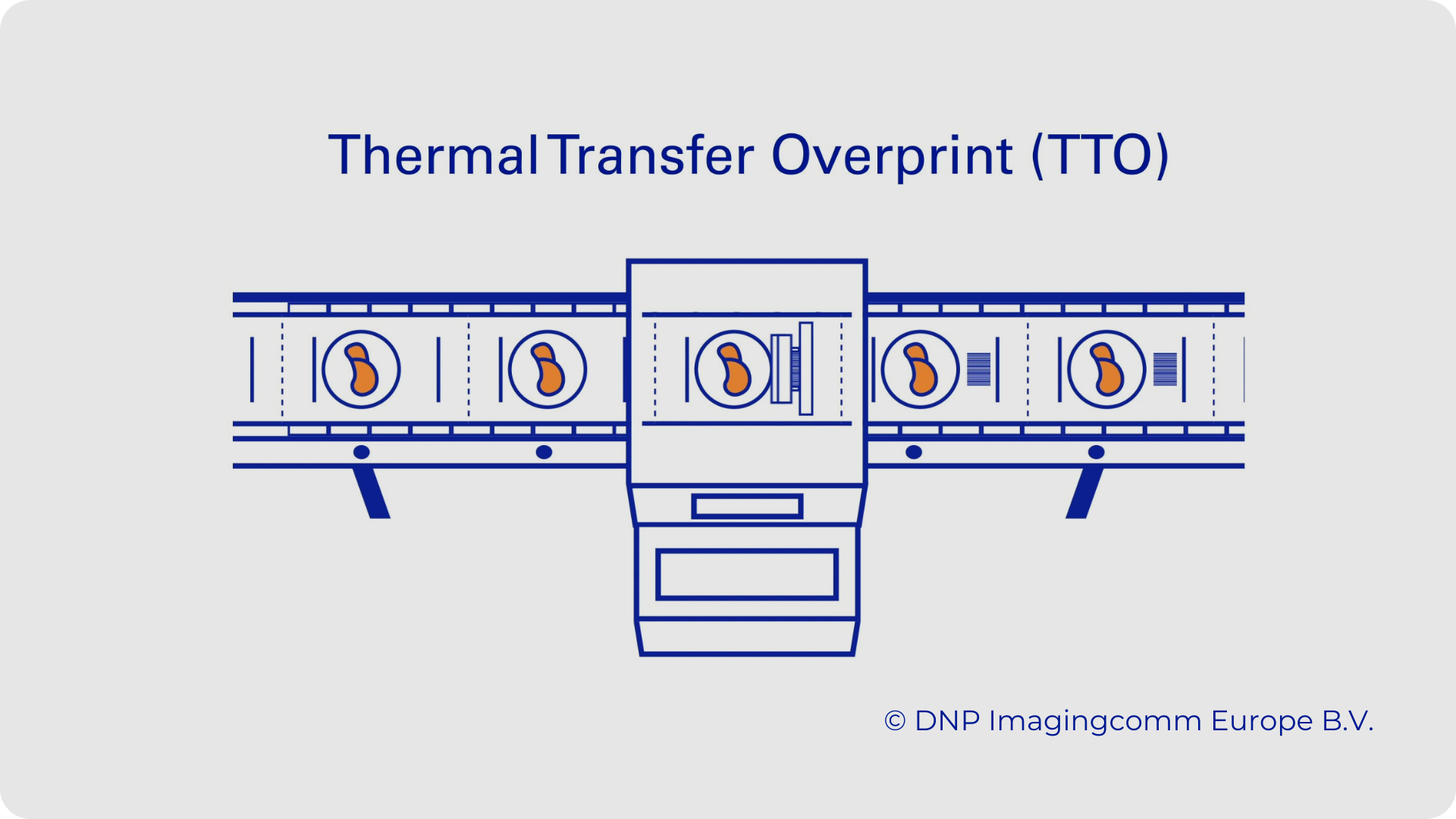

Thermal transfer printing is one of the most commonly used methods for overprinting labels with variable information. For this printing technology you need a thermal transfer printer, labels and a thermal transfer ribbon. Read more information regarding thermal transfer printing.

In order to meet the requirements of different industries, printers and labels, there exist a wide variety of thermal transfer ribbons.

How to choose the most suitable thermal transfer ribbon?

1. Ribbon material

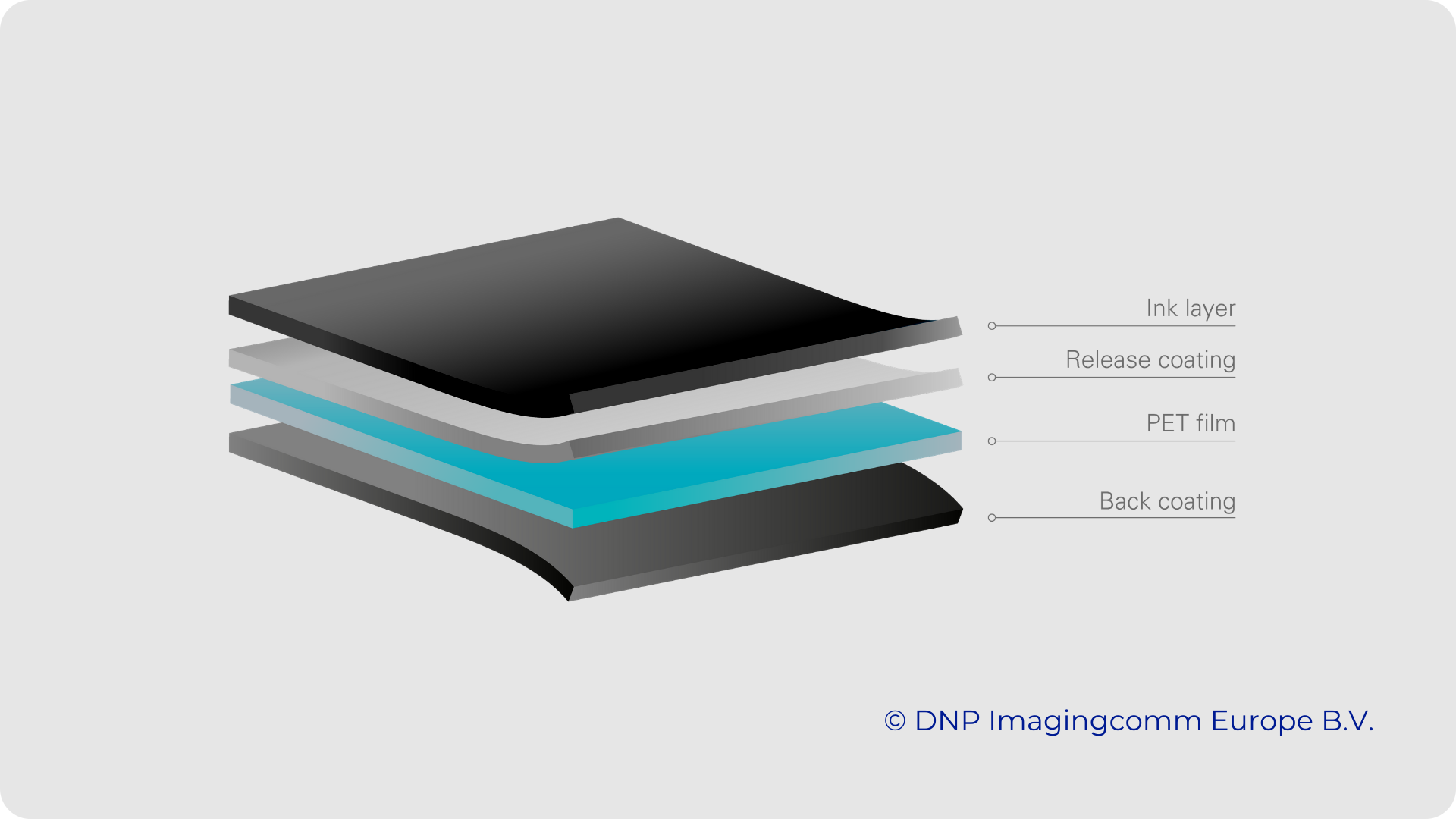

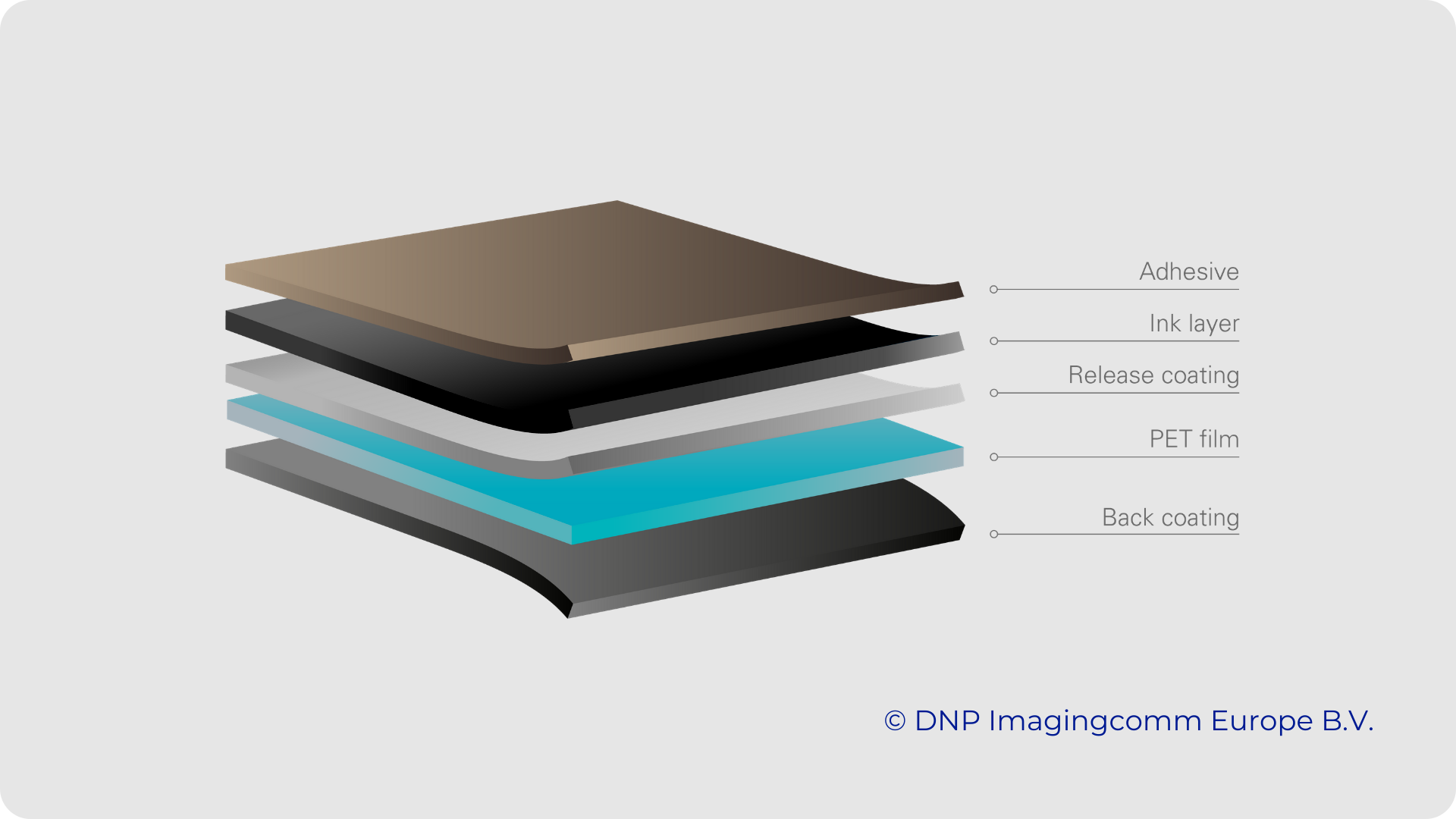

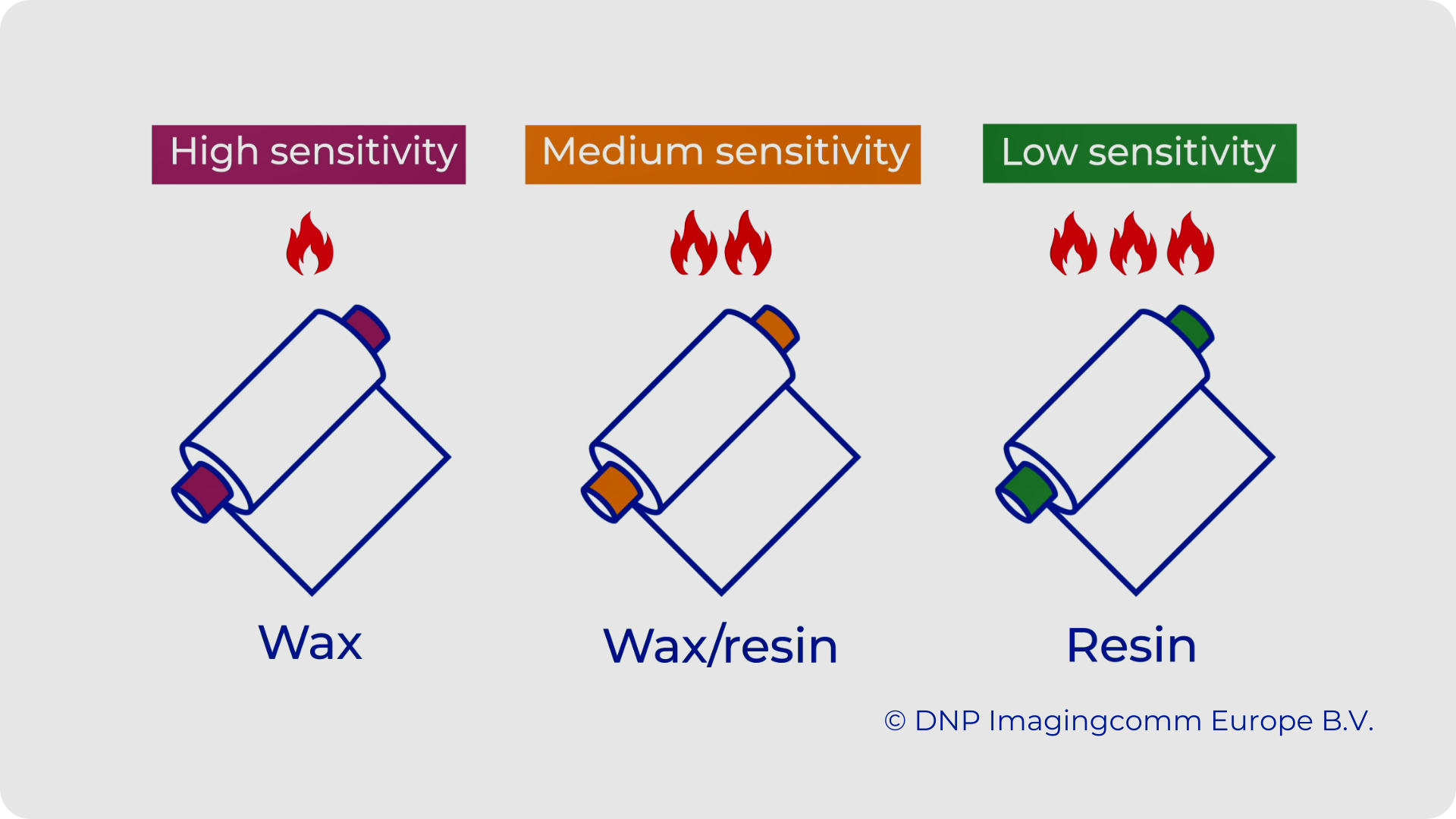

The specific application for which you need the printed labels will determine the strength and durability of the thermal transfer ribbon and the material it is made of. Thermal transfer ribbons can be wax, wax-resin and resin.

Wax thermal transfer ribbons are the most commonly used ribbons for general purpose labeling. One of their biggest advantages is that they have high print sensitivity. This means they achieve excellent results and print quality even in low heat settings. The low temperature protects the printhead and helps prolong its life.

Wax thermal transfer ribbons are the most commonly used ribbons for general purpose labeling. One of their biggest advantages is that they have high print sensitivity. This means they achieve excellent results and print quality even in low heat settings. The low temperature protects the printhead and helps prolong its life.

Wax ribbons also cost less than the other types of ribbons. These advantages mean that wax ribbons are the most economical thermal transfer ribbon choice.

These ribbons achieve a clear imprint with high contrast and density. They are suitable for high-speed printing on various label materials. They work extremely well with rough surface materials, cardboard, non-gloss, semi-gloss and glossy papers and synthetic materials.

However, wax ribbons are not suitable for applications where you require high resistance to smudging and scratching. The imprint is not durable for a long time especially in harsh conditions and it is not heat sensitive.

Therefore, wax ribbons are the ideal solution for general purpose applications with little to no exposure to harsh conditions, where the label will be used for a short amount of time. They find application in storing, transportation, logistics, information management and retail as classic identification labels.

Wax-resin thermal transfer ribbons are commonly used when the application requires medium label durability. The wax-resin printed image is much more resistant to smudging, scratching, moisture and other moderately harsh conditions compared to that of wax ribbons, because these ribbons are enriched with resin. The wax-resin imprint has much better mechanical resistance. It also allows you to print barcodes turned to a 90-degree angle of the printing direction.

These thermal ribbons can achieve a high-quality dense imprint on a wide variety of materials. They are designed for printing labels made of glossy paper, foils (PE, PPE and polyester labels), cardboard, synthetic materials and others.

Due to the quality and relatively excellent durability of print, wax-resin ribbons are used in many industries. E.g. food industry, horticulture, electronics, transportation and some sectors within the pharmaceutic industry.

Resin thermal transfer ribbons are used in specialised applications, requiring long-lasting or permanent imprints of product information. Also when the highest level of durability of the printed image is needed in extremely harsh conditions.

Resin thermal transfer ribbons are used in specialised applications, requiring long-lasting or permanent imprints of product information. Also when the highest level of durability of the printed image is needed in extremely harsh conditions.

They are specifically designed for excellent resistance to mechanical wear, exposure to chemicals and solvents, abrasion, high temperatures of up to 3000C, bleaching agents, sulfuric acid, machine oil, gasoline, detergents and others.

Depending on the application, the resin thermal ribbons are made of two, three or more layers of ink. Every added layer improves the imprint quality. In order to achieve this extreme durability, resin ribbons have lower print sensitivity, i.e., they require more heat to print. All resin ribbons that Dilcom offers, in combination with suitable high-quality labels and thermal label printers, meet the highest global standards for resistance and durability.

Resin ribbons are designed for printing on PE, PPE and polyester labels, satin labels, taffeta, vinyl and others. They are used in the automotive industry, healthcare, electronics, heavy industry, chemical industry, manufacturing, horticulture and the jewelry industry. They can also be used in sectors that require long-lasting printed images in severe conditions.

Resin thermal transfer ribbons are designed for printing on polyethylene, polypropylene and polyester labels, satin labels, taffeta, vinyl and others. They are often used in the automotive industry, healthcare, electronics, the heavy industry, the chemical industry, manufacturing, horticulture, the jewelry industry and other sectors that require that printed images be long-lasting even in severe conditions.

| Wax | Wax-resin | Resin | |

| When are they commonly used? | The most often used thermal transfer ribbons for general purpose applications | Often used in applications with medium resistance requirements | Used for specific applications where you have to meet the highest requirements for resistance and durability |

| Price | Most economical choice | Medium price range | In the highest price range |

| Printhead life | Longer printhead life | Long printhead life | Medium printhead life |

| Labels | Excellent print on paper labels with rough or smooth surfaces | Specially created for printing on labels with glossy papers and synthetic materials | Excellent print on labels made of mainly synthetic materials |

| Color printing | Possible | Possible | Possible |

| Print durability | Low durability compared to the other types of ribbons | Good print durability | Excellent print durability |

| Application | Suitable for logistics, retail, product identification | Suitable for logistics, transportation, the food industry, electronics | Suitable for the pharmaceutical industry, automotive industry, electronics, the chemical industry and others. |

Dilcom offers one more special ribbon type. The textile thermal transfer ribbon is a resin ribbon specifically designed for printing on foil labels and textile satin or taffeta adhesive and non adhesive labels. This ribbon’s imprint is resistant to washing, dry-cleaning, coloring, ironing with temperatures of up to 150°C and stone washing.

The resin textile ribbon has a unique back coating which guarantees even better contact with the printhead of the printer in order to achieve a higher quality printed image and further protect the printhead. The main colors of this ribbon are white, black, green, blue and red. We also offer gold and silver textile ribbons for printing on black satin and taffeta.

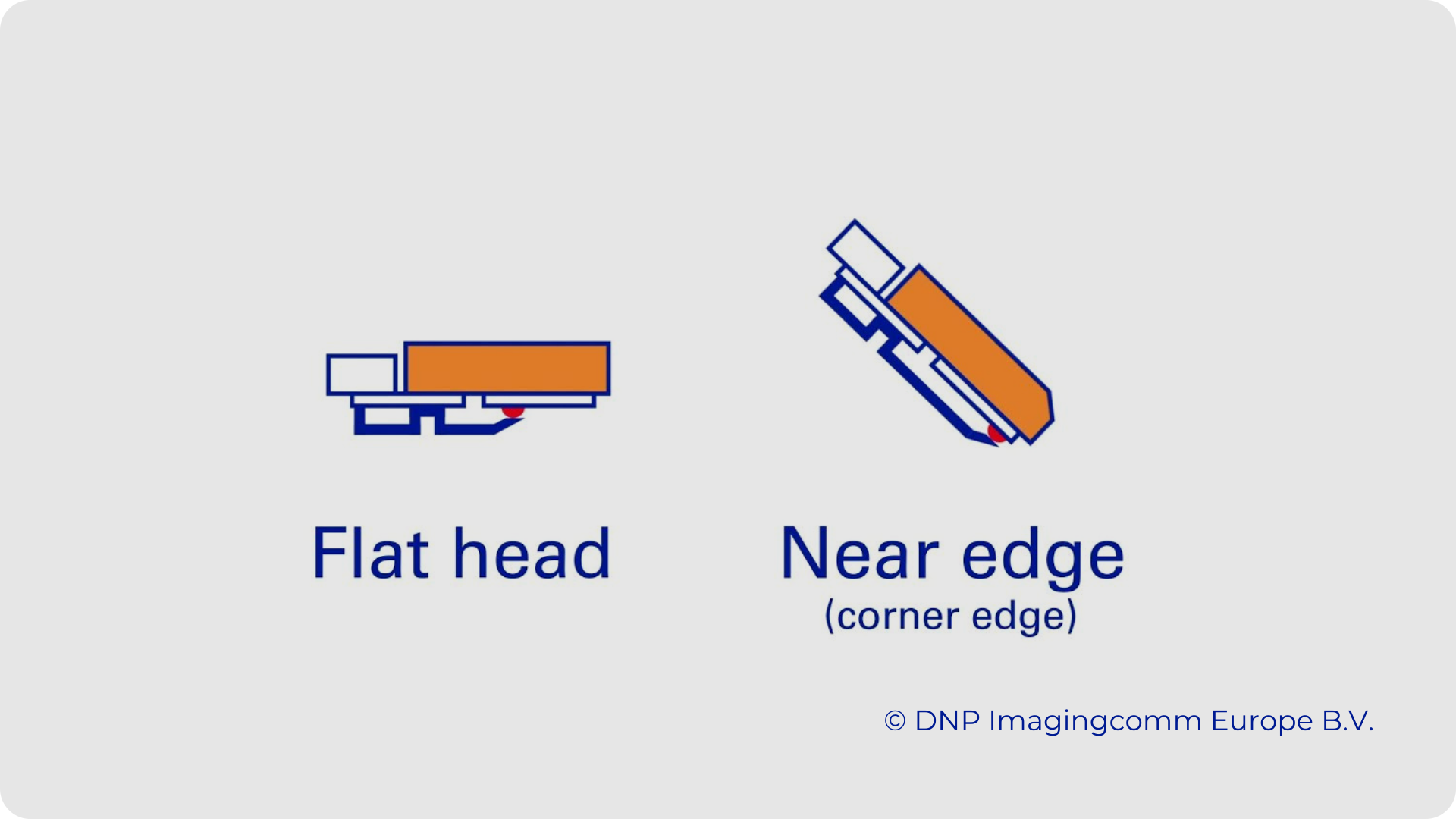

2. What is the printhead of the printer – flat or near-edge?

The print heads of label printers and thermal ribbons can be two different kinds – flat and near-edge.

Flat thermal heads, which are more common, are horizontal. Here the ribbon has longer contact with the media while it passes under the printhead, which applies heat. This continual contact ensures an excellent imprint but slows down the print speed (2 to 10 IPS).

Near-edge printers have a floating printhead, placed at an angle. Here, the ribbons have very brief contact with the labels. This allows for the printing process to be more than twice as fast – 10 to 34 IPS.

3. Size

For an optimal choice, pick a ribbon that is slightly wider than your labels. For example, if the labels are 47mm wide, pick a ribbon that is 55mm wide. It provides printhead protection from the abrasive action of the labels. Thermal transfer ribbons come in different lengths. Shorter ones are designed for desktop label printers and longer ones for industrial label printers.

4. Which ribbon side is the ink on?

According to this specification, there are two types of ribbons: those where the ink is on the inner side (in) and those where it is on the outside (out). Some high performance printers work with both types of ribbons - they automatically recognize the winding direction. But other printers are compatible with only in or only out ribbons.

Innovative applications using DNP’s high-quality Thermal Transfer Ribbons

One company regularly developing innovative ribbons is DNP – a Japanese manufacturer with 145 years of experience in the printing industry. DNP is Dilcom’s long-standing trusted partner, because of our shared devotion to providing high-quality products.

Their resin thermal ribbons which have a holographic imprint are a creative solution for unique labeling of products. They allow printing personalized holographic texts, barcodes or images on labels made of glossy papers, synthetic materials and PVC. The attractive design of these labels creates unique packaging for your products.

The innovative ribbon can also be useful against product counterfeit because the holographic imprint cannot be replicated. Therefore, this ribbon helps protect your brand and prevent loss of revenue due to counterfeiting. You can learn more about the hologram resin thermal ribbons, specially designed by DNP, by visiting this link.

Another innovative DNP ribbon which presents ways to protect your brand and the uniqueness of your products is the UV fluorescent ribbon. This resin ribbon is compatible with all thermal transfer printers. With it, you can print variable information with added UV pigments, invisible to the human eye until lit up by a UV lamp. This unique characteristic makes it easy to identify original products.

The resin UV ribbon is available with a transparent coating. Its imprint is very durable and resistant on papers and synthetic labels. This thermal ribbon is mainly used for protection and as proof of product genuineness. However, it can be used for interesting marketing purposes such as brand advertising in dark spaces with UV lighting such as night clubs.

For interesting and fun applications, DNP also offers a resin thermal transfer ribbon for scratch-off labels. It is most often used for lottery tickets and gift cards. The scratch-off ribbon is also a perfect choice for product promotion through “erase and win” type of games. It is suitable for labels made of a wide range of materials such as ABS, polyester, PE, PPE and PVC.

For more information on its interesting applications and the characteristics of the DNP scratch-off resin ribbon, please visit this link or contact Dilcom’s authorized specialists at sales@dilcom.com.

In conclusion, the thermal transfer printing method has many advantages: high-quality imprint, durability and resistance. For optimal results, the printer, ribbon and application need to be carefully coordinated.

Dilcom offers wax, wax-resin, resin and textile thermal transfer ribbons, suitable for all types of thermal transfer printers. We know that harmonizing the ribbon material, size and type with your application is a tough task.

That is why Dilcom’s specialists with gladly help you in any stage of choosing your ideal thermal transfer ribbon.

Contact them at sales@dilcom.com.

Post comment