Date: 13 Apr 2021

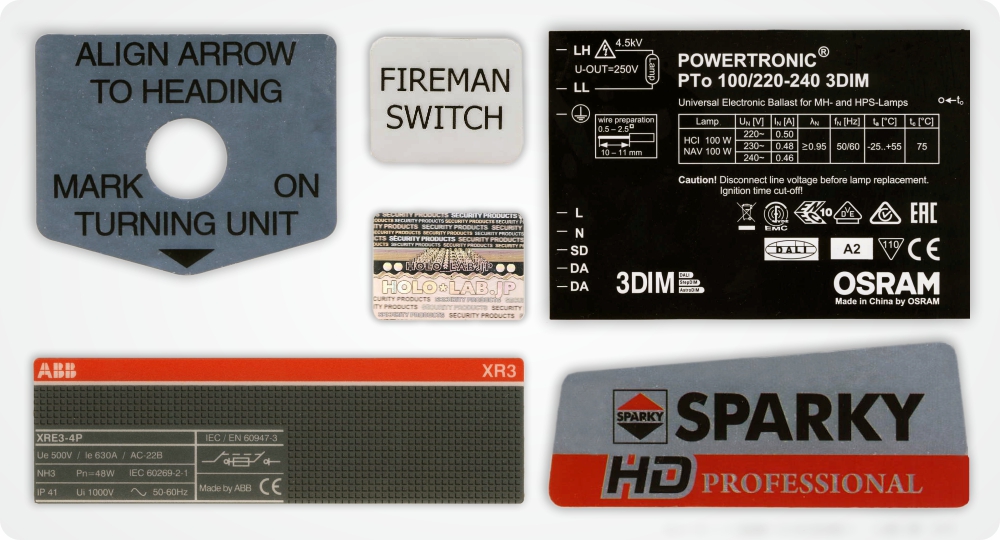

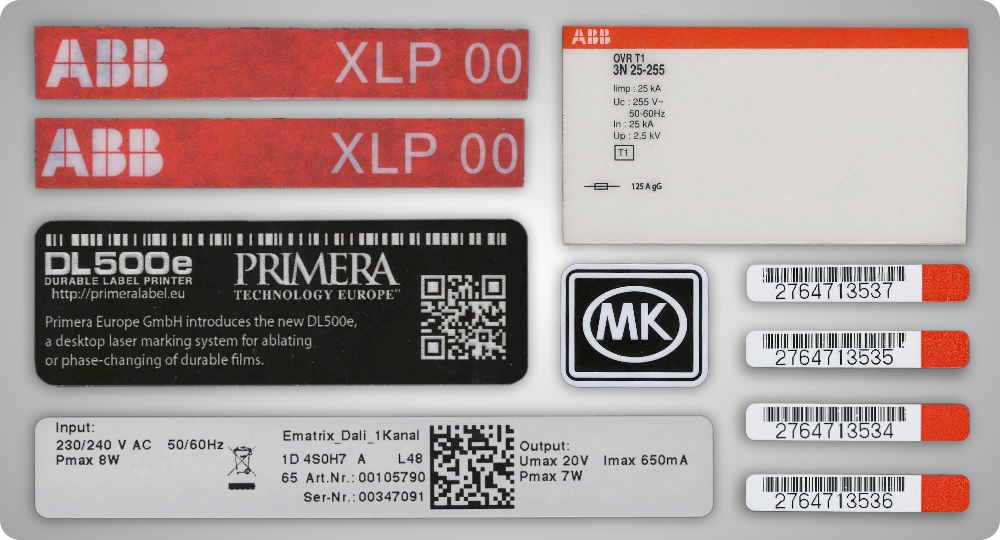

Industrial labels are most often polyester, PVC or vinyl labels, resistant to harsh weather and operating conditions. These labels with industrial applications must be durable and long-lasting as well as not tear, fade, crack or peel off. Here, label aesthetics are of secondary importance after their durability and functionality.

Industrial stickers find application in many different sectors: transportation, automotive, healthcare, electrical engineering, military equipment, mechanical engineering, shipbuilding and others.

Main purposes of industrial labels

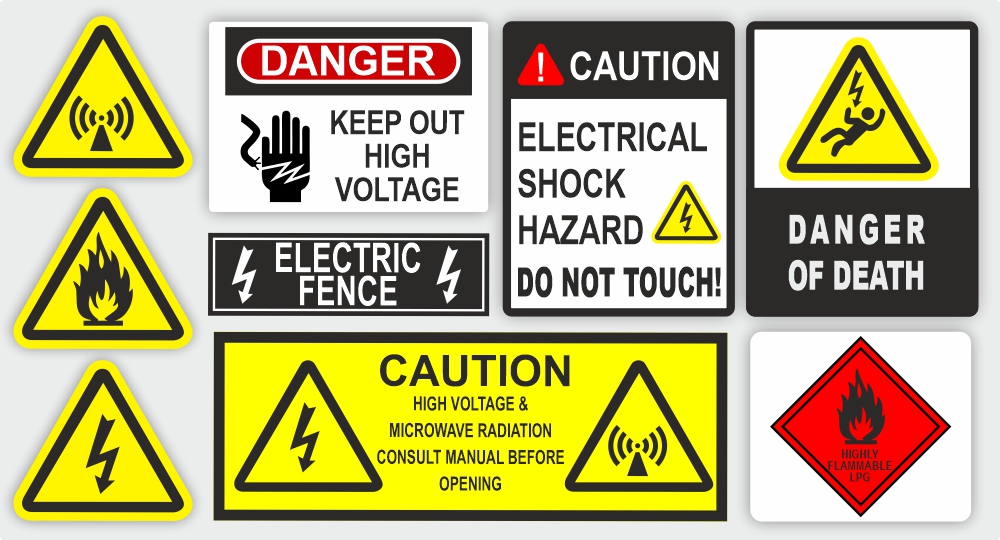

For most applications these labels have to guarantee long-term readability and durability in harsh conditions. Depending on their function, they can carry important information regarding safe use, potential dangers and operating instructions. This is extremely important for ensuring a safe working environment.

Industrial labels can also serve to guarantee the originality of the product, show proof of counterfeit and quality control. In some cases, these labels can protect customers from accidents, potential hazards or purchasing of fake or forged products.

Industrial stickers can have a barcode, QR code, RFID chip or serial number tags. They facilitate rapid inventory, aid logistics and product tracking. They are often imprinted with details about calibration, inspection data, preventative maintenance schedules, reminders for further servicing needs and ownership indicators.

These custom labels have to be legible, durable and adhered securely. Failure to do so may result in unsuccessful inspections or even legal issues if operating and safety standards are not met.

Necessary durability and quality of industrial labels

When choosing your industrial labels, consider how and where your products will be transported, stored and used. That will determine the degree of durability that the manufactured labels need to have.

For instance, some equipment is often exposed to high temperatures. These equipment labels should be made with heat-resistant materials and a very strong durable adhesive. This ensures that the product labelling will be in excellent condition for many years.

Dilcom produces a wide range of industrial labels using 3M, Flexcon, Lintec, Avery Dennison, Raflatac and Arconvert materials. Depending on our clients’ specifications, they can be durable to:

- Chemical solvents and fats

- Extremely high or low temperatures

- Indoor and outdoor use

- Weather conditions

- Fuels and oils

- Hydraulic fluids

- Cleaning agents

- Brake fluids

- Exposure to UV light and radiation

- Salt water immersion

Materials to meet different specifications

Depending on their application, industrial label materials have to be robust, flexible and legible throughout the life cycle of the product. They also have to be resistant to chemicals, UV light, extreme temperatures and humidity. Dilcom’s team can present you with an innovative, state of the art solution specifically tailored to your distinct label requirements.

Dilcom is a partner and converter of 3M in the non-graphic products sector. We have the technical capability to laminate, die cut and cut a wide variety of adhesive tapes, foam materials and foils. We can also do this for electrical insulating, masking tapes and other flexible materials with any size, colour and shape.

The high-quality materials we use to produce our industrial labels allow color clarity and image accuracy. They also allow printing of easy-to-read barcoded labels. They can be permanently adhered to any surface and prevent illegal tampering with equipment.

Industrial labels application

Industrial labels are applied in a very wide variety of sectors. This is done as to create a safe working environment and ensure secure tracking of products and equipment.

For example, in electrical engineering, seal labels are often placed on cables or electrical switchboards. Due to the high levels of potential danger in this sector, accurate warning labeling can significantly reduce accidents.

In the healthcare sector it is often necessary to thoroughly clean equipment with cleaning agents containing alcohol. The industrial adhesive labels which are placed on medical equipment have to be of the highest possible quality, readability and durability.

The transportation trade also requires durable industrial stickers. Identification labels that can withstand the harshest weather conditions and dousing with salt water have to be used in maritime transportation. In land transportation you need eye-catching long-lasting labels. They should not deform, fade away, crack or peel off during long journeys in many different weather conditions.

Industrial printed labels also have to clearly display your brand and be a visual representation of your commitment to safety. They have to be legible and placed in a clearly visible spot on your product to aid daytime and nighttime visibility.

How to order your personalized high-quality industrial labels

Dilcom Bulgaria is manufacturer, specializing in industrial label printing, with 20 years of experience. Our highly qualified team of designers, engineers and specialists can work with you during every stage of the label selection process. You can depend on us to present you with a high-quality customized product at competitive prices in a timely manner.

We will carefully asses your product’s environment and offer you an innovative solution, meeting your long-term durability requirements. Our specialists have one key consideration - strictly adhering to the highest industrial sector quality standards.

Contact the specialists at Dilcom at sales@dilcom.com and we will help you make the best decision for your industrial labels.

Post comment