Date: 11 Mar 2021

Labeling machines serve to quickly and professionally apply or simultaneously print and apply labels with different sizes and designs onto products with various surfaces and shapes.

Read this article to learn about the main advantages of label applicators and how to choose the right labeling system. We will also look at their ever-growing significance in the pharmaceutical industry.

Main advantages of labeling machines:

Labeling machines apply labels neatly and precisely onto your products.

During the manual application process an operator cannot apply labels to two different products in the exact same position. Sometimes they adhere to the product at a slight angle, become creased or there are air bubbles below them. This creates an unpleasant label appearance, thus possibly preventing your customers from preferring your product.

These problems are avoided when using a labeling system which guarantees precise and accurate label adhesion on all surfaces and unique product shapes.

The labeling systems are extremely high-speed machines and significantly increase productivity as well as printing and application efficiency. They allow the labeling of thousands of products per hour and can work 24 hours a day.

Using a labeling system leads to a substantial decline in errors.

During the manual label application process in fast-paced production bases, human errors like applying industry labels to the wrong product or incorrect label adhering are common. In contrast, when working with a contemporary labeling machine, equipped with a high-quality system for quality control, these errors are completely avoided. This reduces the risk for the manufacturer, ensures greater productivity and saves materials.

Labeling machine use saves your staff time and reduces labor costs.

When product labels are adhered by a machine, your operators can fulfil other company duties, thus further enhancing productivity. The machines are easy to use and maintain. Operators only need short training to be able to choose a print/apply program which is pre-saved on the system by your specialists.

Labeling machines allow for a large quantity of programs containing product parameters to be pre-saved. This function providing fast readjustment when switching between products.

Integrating one or more labeling machines into your production lines guarantees that your business will be prepared for future requirements.

Companies often need to diversify their label portfolio and label application style. This might be needed because of company growth or new legal labeling requirements being established. The technologically advanced labeling systems are extremely adaptable so you can easily add new programs according to the latest requirements. They can print many different types of labels such as foil, paper, tamper evident or durable labels.

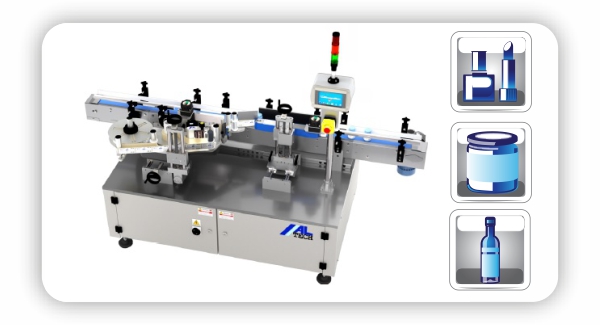

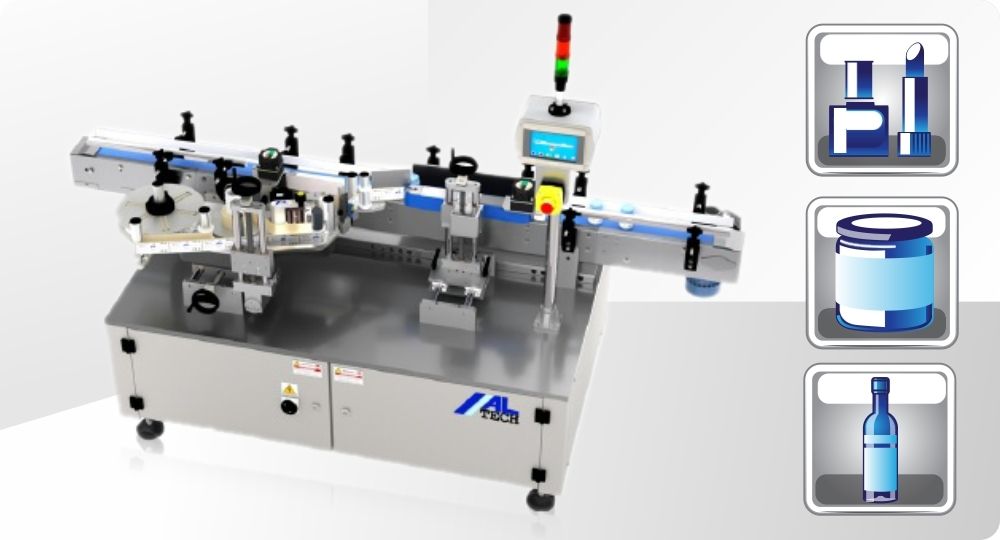

Depending on their level of technical ability, some systems can be configured according to the product and client needs. These labeling machines can label products with all shapes, surfaces and sizes – from a small glass nail polish bottle to 5-liter plastic tubes. Dilcom offers various kinds of label printing machines for flat surfaces and cylindrical products.

Instructions on how to choose the right labeling system

There are many different types of automatic and semi-automatic systems which have diverse configurations and applications.

Semi-automatic labelers fall into the preliminary category of automatic labeling. When using these applicators, an operator has to manually place the products in the machine and start the labeling process. The labelers can label products with many different shapes.

Semi-automatic labelers fall into the preliminary category of automatic labeling. When using these applicators, an operator has to manually place the products in the machine and start the labeling process. The labelers can label products with many different shapes.

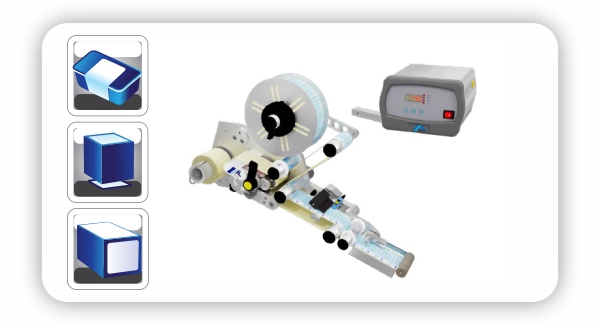

Some semi-automatic machines can also be used in collaboration with a barcode or thermal transfer professional label printer. This device can print variable data such as date, time, barcode and batch number at the moment of labeling

Handheld label applicators help increase productivity and are suitable for small to medium production facilities. They can be used in collaboration with label dispensers even in home offices without the need for wi fi.

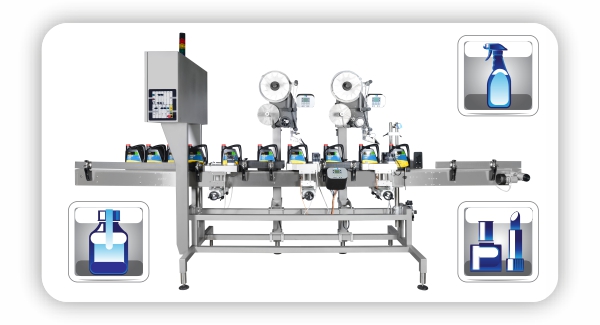

Automatic labeling machines can print, apply, code and inspect labels onto different products. They operate with pre-set programs containing specific requirements for every labeling stage. This process is entirely automated when using these systems. Automatic labelers have extremely high quality and are technologically advanced, and depending on their configuration, allow the labeling of products with all possible shapes, sizes and surfaces.

Some of them can be integrated with a system for additional printing of variable information. They can also be used with special inkjet printers or laser marking devices which ensure high standards of quality, safety and productivity. The automatic label applicators can be configured according to the product and client specifications. They are suitable for any production base and industry.

In addition to the degree of automation, in order to choose the most suitable labeling machine, you need to consider the label size, necessary speed and location of the product label.

Application in the pharmaceutical industry

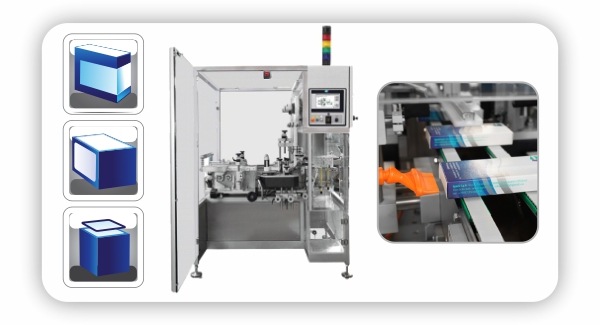

One of the most significant applications of the technologically advanced labeling machines is in the pharmaceutical industry. Here labeling helps to identify the product. But it also serves to display information that is very important to patients such as medicine purpose, dosage instructions, expiry date, list of ingredients and others.

In order to optimize the productivity of the labeling process for medical products and vaccines it is necessary to integrate an automatic labeling system into their production lines. This allows rapid and easy serial number application and product tracking, which in turns expedites the production process. If the labeling process is not automated, the possibility of errors is significantly greater and can even result in product recall.

In conclusion, semi-automatic and automatic applicators are labeling solutions that increase productivity and present new opportunities for marking products in attractive ways.

Dilcom offers a wide range of high-quality labeling systems. These machines apply adhesive labels with all shapes and designs quickly, efficiently and with precision. In this way they add immense value to your products.

If you require more information, please email sales@dilcom.com .

Post comment