Date: 04 Oct 2021

Proper label roll storage

Proper label roll storage

The process from the inception of a product idea to its manufacture and labeling is difficult and long. The Dilcom team is involved in this process and helps their clients create a final product that is labeled in a high-quality and unique way. But we believe that our business relationship does not end when we deliver the printed labels because we want to make sure that you can then use your labels in the most optimal way.

Storing labels may seem simple and not significant at first, but it is a very important factor in the overall look and success of your product. In this article you can see our label storage guidelines which will help you keep your labels in great condition as well as preserve their qualities, adhesive and functionality for a longer period of time.

Do not store labels at very low or high temperatures

The suitable temperature for storing most types of labels - direct thermal labels and foil labels (polyester labels, polypropylene labels, polyethylene labels), etc. - is between 15°C and 25°C (59°F - 77°F). This is recommended for both the storage period and while applying the labels. Exposure to temperatures higher than 25°C for an extended period of time should be avoided because heat can damage the labels.

High temperatures can cause adhesive bleed - a process where the adhesive can penetrate the other layers of the labels. This renders them unsuitable for overprinting with a thermal transfer printer or for application by an automatic or semi-automatic applicator. Excessively low storage temperatures can also damage the adhesive, especially if it goes through a freezing process. This will cause it to permanently lose its adhesive properties.

Do not store your labels in very low or high humidity

When labels are in a humid environment, the adhesive or paper absorbs this moisture and as a result, their corners may begin to bend, peel or shrink. For direct thermal labels, the direct thermal coating gets destroyed and their sensitivity is reduced. The ideal humidity to maintain the excellent quality of most labels is around 50%. It is recommended that you store your labels in plastic or non-transparent sealed packaging in areas with low humidity in order to avoid the adhesive drying out.

Avoid UV light exposure

Direct sunlight and UV rays will cause labels to discolor, fade or blacken over time, thus damaging the label design. If the environment you are storing your labels in is exposed to these conditions and they cannot be moved to another location, storing them in opaque sealed packaging will also help and protect them from harmful light.

Do not expose your labels to dust or other particles

Storing in the packaging mentioned above is also recommended to avoid dust contamination. This is particularly important for labels which will be applied with applicators, as well as for direct thermal labels and thermal transfer labels. If these types of labels are dusty, the mechanisms of the applicators and thermal printers will wear out because the dirt particles act like fine sandpaper.

When you receive your labels from Dilcom, they will be pre-cleaned and carefully packaged to avoid damage during the logistics operations. This original packaging provided by us is often one of your best options for protection from moisture and contamination.

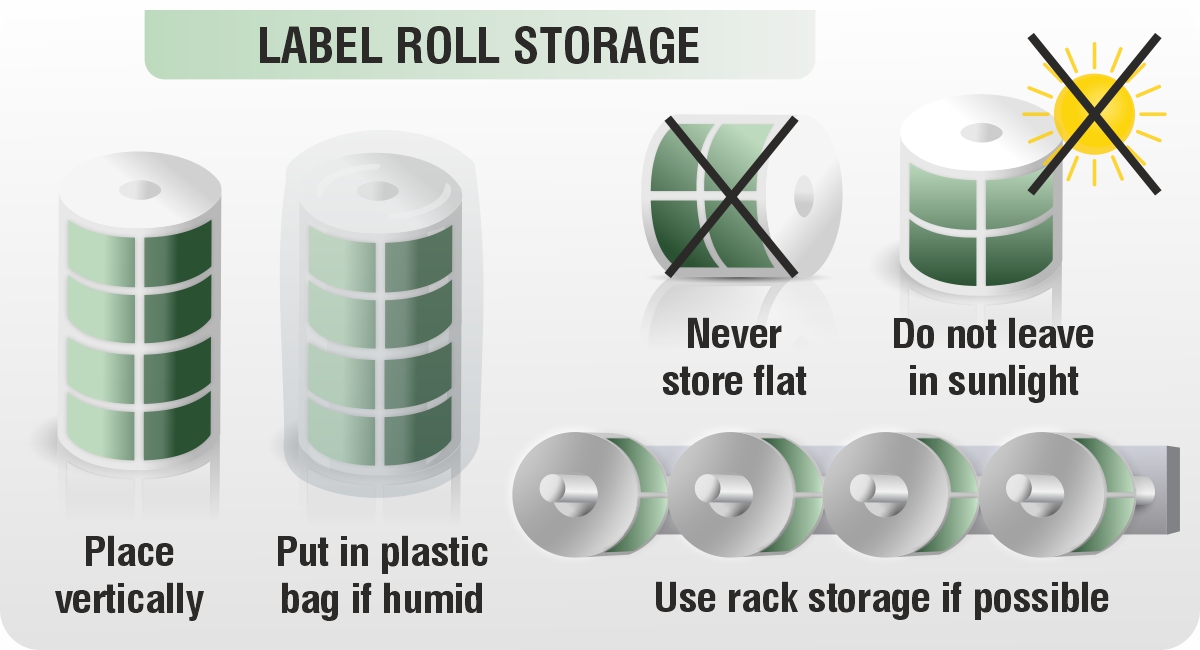

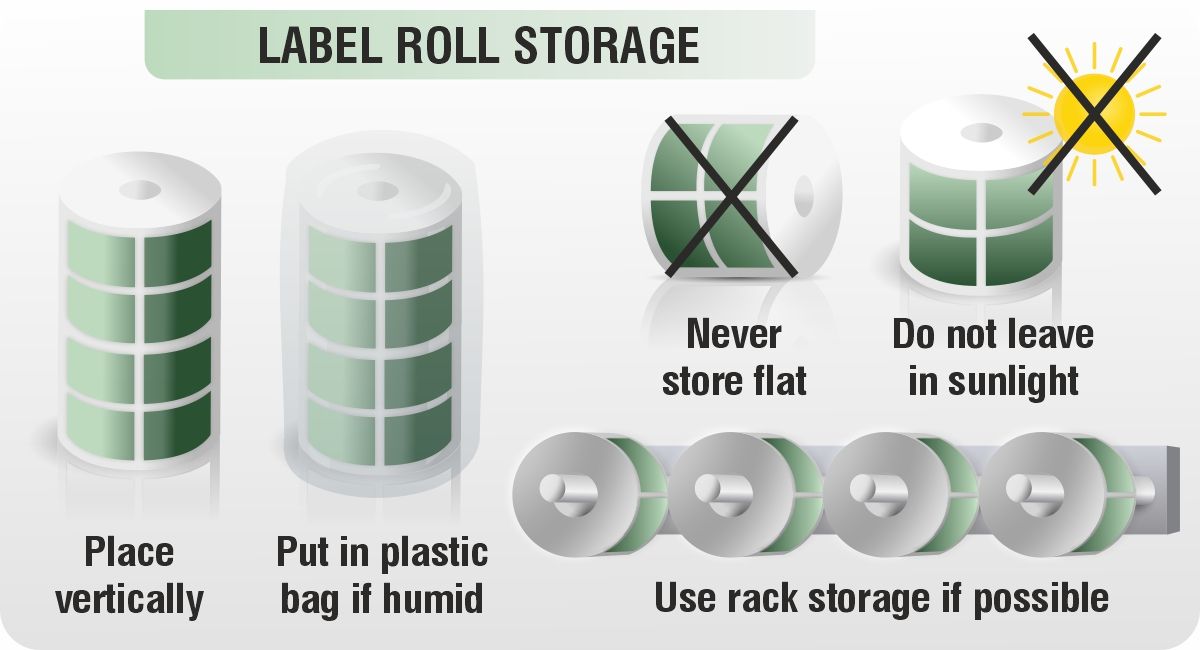

Place label rolls in a specific position for storage

Place label rolls in a specific position for storage

If you don't have a dedicated roll label storage rack, there are several easy ways to store labels in order to keep them in great condition. It is best to stack them vertically on top of each other on a clean, smooth surface when not in use.

The general rule is that you shouldn't place more than three rolls on top of each other for a long period of time because the weight can damage or deform the bottom rolls. This rule varies depending on the weight, shape and size of the rolls.

Do not store labels for too long

If labels are stored for a long time, it can affect the quality of the print and adhesive. The general rule that applies to almost all labels is that you should not keep them in storage for more than one year. As for direct thermal labels, the maximum is six months as they are very sensitive to heat, light and moisture.

If labels are stored for a long time, it can affect the quality of the print and adhesive. The general rule that applies to almost all labels is that you should not keep them in storage for more than one year. As for direct thermal labels, the maximum is six months as they are very sensitive to heat, light and moisture.

In conclusion, when manufacturers consider all factors that could affect the quality of their product labels, they often overlook the storage conditions and methods. However, this is an important factor as improper storing of labels can significantly reduce their quality or render them unusable. Follow the outlined tips and your labels will have a longer life span.

If you require any further information regarding the correct way to store your labels, please contact our specialists at sales@dilcom.com and they will advise you so that you can use your materials in the most efficient way possible.

Post comment